Boeing 787

Boeing 787 user+1@localho… Tue, 09/06/2022 - 21:17 Boeing’s 787 is a family of widebody airframes produced by the Chicago-based manufacturer, with three variants of the series currently certified. Described during its development as being “a...

Boeing’s 787 is a family of widebody airframes produced by the Chicago-based manufacturer, with three variants of the series currently certified. Described during its development as being “a new super-efficient, midsized airplane,” the 787 was originally designated the 7E7, a designation that symbolized the improvements that Boeing sought to make in areas such as economics, efficiency and environmental performance. Formally launched in April 2004 with a 50-airframe order from Japan’s All Nippon Airways (ANA), the first 787 to fly, be certified and enter service was the -8, a variant that was symbolically rolled out of Boeing’s facilities at Paine Field in Everett, Washington on July 8, 2007 (7/8/07). Following that rollout ceremony, the first -8 airframe—registered as N787BA and designated ZA001—made its first flight, which lasted slightly more than 3 hr., from Paine Field on Dec. 15, 2009. That first 787 was powered by a variant of Roll-Royce’s Trent 1000 engine; however, all three variants are also approved to be equipped with General Electric’s (GE) GEnx-1B engines. According to engine manufacturer GE Aviation, the first flight of a GEnx-1B-powered 787 took place on June 16, 2010, from Paine Field.

Twenty months after the airframe’s first flight, and upon the completion of a flight-test program that exceeded 4,800 hr., the 787-8 was simultaneously certified by the FAA and European Union Aviation Safety Agency (EASA) in August 2011. Although at the time it was launched, the -8 was planned to enter service in 2008, the first 787 delivery—an airframe registered as JA801A—was made to ANA on Sep. 25, 2011, with ANA subsequently placing the type into service between Tokyo Narita Airport and Hong Kong on Oct. 26, 2011. Following the certification of the GEnx-1B-powered 787-8—Boeing received an amended type certificate (ATC) in March 2012 that approved GEnx-1B engines for the -8—the first such airframe was delivered to Japan Airlines (JAL) on March 26, 2012.

The next variant of the 787 series to be developed was the -9, with Air New Zealand serving as that variant’s launch customer. As was the case with the -8, the first flight of the larger -9—which took place on Sep. 17, 2013, from Paine Field—was powered by a variant of Rolls-Royce’s Trent 1000 engine. That flight, which lasted 5 hr. 16 min., was performed by a -9 registered as N789EX and designated ZB001, while the first flight of a GEnx-1B-powered airframe—registered N789ZB and designated ZB021—took place slightly more than two months later on Nov. 19, 2013. Specific to the equipped engines, the Rolls-Royce and GE-powered airframes were equipped with the “Package C’ version of the Trent 1000 [and] the upgraded ‘PIP II’ variant of the GEnx-1B.” Subsequent to the completion a flight-test program that included “more than 1,500 hr. of flight testing,” Boeing received an ATC for the -9 in June 2014, a certification that was validated by EASA on the same day. Although Air New Zealand was the launch customer and received the first delivery of a -9, registered ZK-NZE, on June 30, 2014, it was ANA that was the first operator to place the variant into service. ANA, which received their first -9 on July 27, 2014—registered as JA830A—placed that airframe into service to domestic destinations from Tokyo Haneda Airport on Aug. 7, 2014, just ahead of Air New Zealand’s entry into service with the -9 between Auckland and Sydney on Aug. 9. Subsequently, the first delivery of a GEnx-1B-powered -9 took place several months later on Sep. 4, 2014, with a delivery to United Airlines.

Launched on June 18, 2013, at the Paris Air Show, the first flight of the largest 787 variant, the -10, was made from Charleston International Airport in South Carolina, the location of Boeing’s second 787 production line. In keeping with the first flights of the smaller 787 variants, the first flight of the -10—which took place on March 31, 2017, was performed by an airframe registered as N528ZC and designated ZC001 and which lasted 4 hr. 58 min.—was powered by a pair of Rolls-Royce’s updated Trent 1000 TEN engines. The first flight of a GEnx-1B-powered airframe, registered as N548ZC, took place on May 2, 2017, with that airframe eventually being delivered to United on May 21, 2019. Following a flight-test program that included three airframes—two Trent 1000-powered and one GEnx-1B-powered—and which “accumulated about 900 test hours,” Boeing received the ATC for the -10 in January 2018. Singapore Airlines subsequently received the first -10 airframe, registered as 9V-SCA, at Boeing’s Charleston facilities on March 25, 2018—the first of 49 ordered by the carrier—with the type entering service a little more than a week later on April 3, 2018. Intended for use on Singapore’s “regional routes”—which are “loosely defined as up to about 8-hr. flights”— the company began operating the -10 to Osaka, Japan on May 3, 2018, Perth, Australia on May 7, Tokyo Narita on May 18 and Nagoya, Japan on July 28. The first operator to receive a GEnx-1B-powered -10 was Etihad Airways, which received their first airframe—registered as A6-BMA—on Oct. 30, 2018.

Regardless of any differences between the -8, -9 and -10, all share a common type certificate that is held by The Boeing Company of Renton, Washington.

|

787 Variant |

FAA Certification Date |

|

787-8 |

Aug. 26, 2011 |

|

787-9 |

June 13, 2014 |

|

787-10 |

Jan. 19, 2018 |

Cabin and Passenger Capacity

According to Boeing’s “Airplane Characteristics for Airport Planning” document for the 787, the -8’s typical two-class capacity of 242 passengers can be accommodated in a cabin that includes 24 business-class seats and 218 economy-class seats. While that document does not provide information on configurations that would accommodate the -9’s 296-seat two-class capacity, the same planning document does note that variant’s typical interior arrangement as including 290 seats that are divided between 28 in business class and 262 in economy class. Similar to the -9, the cabin configuration described in the airport planning document of the -10 depicts a 330-seat cabin, not the 336-seat layout that is promoted in Boeing’s marketing materials. The typical arrangement described in the planning document includes 32 business-class seats and 298 economy-class seats, with the seat pitch of the business and economy-class seats on all three variants noted as 85 in. and 32 in., respectively. However, in Boeing’s typical configurations, several of the business-class seats—four on the -8, eight on the -9 and 10 on the -10—have a reduced pitch of 75 in., while 30 seats in the -9’s economy-class cabin have a pitch of 33 in. In contrast to those available configurations, the FAA type certificate data sheet (TCDS) for the 787 notes that the -8, -9 and -10 have maximum certified passenger capacities of 381, 420 and 440, respectively.

In terms of cabin features, Boeing promotes the 787’s size—of the overhead bins and windows, as well as the cabin more broadly—lighting and air quality as being of particular importance to both operators and passengers. Described as having a cabin that is “wider than that of the airplanes it replaces,” the size of the entryway and windows are highlighted—with the windows promoted as being “the largest windows of any jet”—as is its “vaulted ceiling.” Boeing also promotes the cabin’s light-emitting diode (LED) lighting, the filtration and humidity of the air that enters the cabin and the pressurization of the cabin itself. The combination of those three factors is marketed as making the cabin air “feel less dry” and helping to reduce fatigue. Additionally, the increased stiffness of the 787’s composite construction allows for a cabin altitude of 6,000 ft., in comparison to the 8,000-ft. standard cabin altitude of conventional, non-composite-fuselage airplanes.

Cargo Capacity

Supplementing the space in the 787-8’s cabin is 4,826 ft.3 of lower-deck cargo space that can accommodate 16 LD-3 containers in the forward compartment and 12 such containers in the aft compartment, as well as 402 ft.3 in the bulk-cargo compartment. On the -9, the lower-deck cargo space increases to 6,090 ft.3, the number of LD-3 containers that can be accommodated in the forward and aft compartments increases—to 20 and 16, respectively—and the bulk-cargo volume remains unchanged. For the -10, the total volume (6,722 ft.3) and forward and aft compartment LD-3 capacity (22 and 18) are increased, while the bulk-cargo volume once again remains the same.

Avionics

Flight crews operate the 787 using a Collins Aerospace avionics suite that includes five 15-in. multifunction displays (MFD) that are described as “provid[ing] more than twice the area as those used on the 777.” Despite having larger displays than the 777, Boeing promotes the “flight-deck commonality between the 787 and 777,” and the fact that this commonality can enable airlines to use “mixed-fleet flying” that allows the “scheduling [of] pilots to fly more than one kind of airplane.” With regard to the differences between those types and the training that is needed, Boeing states that “only five days of training” are required for 777 pilots to fly the 787, with the two types sharing a common pilot type rating.

Mission and Performance

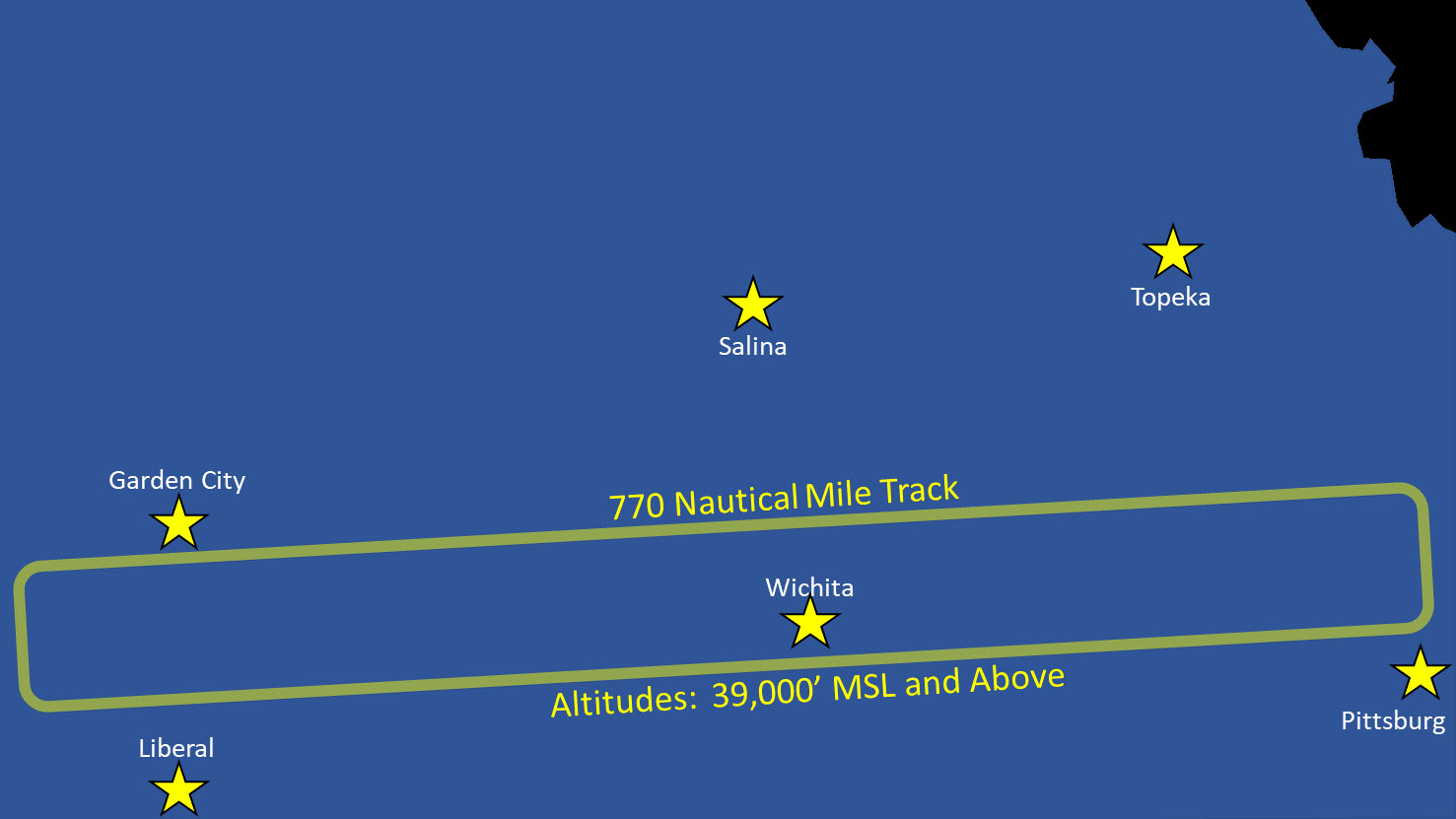

Described as being “designed for medium-to-long haul flights,” Boeing also promotes the 787’s ability to enable new non-stop flights, with the number of “new point-to-point routes” made possible by the 787 since the -8 entered service numbering over 200. Boeing says it is the type’s “fuel efficiency and range flexibility” that allow airlines to begin serving such routes. The primary competition for the 787 is Airbus’ A330neo (new engine option) series of airframes.

|

Comparison: 787 and A330ceo/neo Specifications |

|||||||

|

|

787-8 |

787-9 |

787-10 |

A330-200 |

A330-300 |

A330-800 |

A330-900 |

|

Maximum Certified Passenger Capacity |

381 |

420 |

440 |

406 |

440 |

406 |

440 |

|

Typical Two-Class Capacity |

248 |

296 |

336 |

247 |

300 |

257 |

310 |

|

Maximum Range (nm) |

7,355 |

7,635 |

6,430 |

7,250 |

6,350 |

7,500 (242 metric tons) |

6,550 (242 metric tons) |

|

8,150 (251 metric tons) |

7,200 (251 metric tons) |

||||||

|

Engines (2X) |

General Electric GEnx-1B |

General Electric CF6 |

Rolls-Royce Trent 7000 |

||||

|

Rolls-Royce Trent 1000 |

Pratt & Whitney PW4000 |

||||||

|

Rolls-Royce Trent 700 |

|||||||

|

Maximum Takeoff Weight (MTOW)(lb.) |

502,500 |

560,000 |

533,519 |

553,360 |

|||

|

Wingspan |

197 ft. 3 in. |

197 ft. 10 in. |

210 ft. |

||||

|

Length |

186 ft. 1 in. |

206 ft. 1 in. |

224 ft. 1 in. |

193 ft. |

208 ft. 10 in. |

193 ft. |

208 ft. 10 in. |

|

Height |

55 ft. 6 in. |

55 ft. 10 in. |

57 ft. 1 in. |

55 ft. 1 in. |

57 ft. 1 in. |

55 ft. 9 in. |

|

Boeing notes that the ranges listed above are for the -8, -9 and -10 are based on two-class capacities of 242, 290 and 330 passengers, respectively. Regarding performance limitations, all three variants have a common maximum operating limit speed (MMO) of 0.90 Mach, while maximum operating altitude varies between 43,100 ft. for the -8 and -9 and 41,100 ft. for the -10.

Variants

|

787 Specifications |

|||

|

|

787-8 |

787-9 |

787-10 |

|

Maximum Certified Passenger Capacity |

381 |

420 |

440 |

|

Maximum Range (nm) |

7,355 |

7,635 |

6,430 |

|

Engines (2X) |

General Electric GEnx-1B |

||

|

Rolls-Royce Trent 1000 |

|||

|

Maximum Takeoff Weight (MTOW)(lb.) |

502,500 |

560,000 |

|

|

Wingspan (ft.) |

197 ft. 3 in. |

||

|

Length (ft.) |

186 ft. 1 in. |

206 ft. 1 in. |

224 ft. 1 in. |

|

Height (ft.) |

55 ft. 6 in. |

55 ft. 10 in. |

|

|

787-8 Engines |

787-9 Engines |

787-10 Engines |

|||

|

Trent 1000 Variants |

GEnx-1B Variants |

Trent 1000 Variants |

GEnx-1B Variants |

Trent 1000 Variants |

GEnx-1B Variants |

|

Trent 1000-A |

GEnx-1B64 |

Trent 1000-A2 |

GEnx-1B67/P2 |

Trent 1000-J3 |

GEnx-1B74/75/P2 |

|

Trent 1000-A2 |

GEnx-1B64/P1 |

Trent 1000-AE3 |

GEnx-1B70 |

Trent 1000-K3 |

GEnx-1B76/P2 |

|

Trent 1000-AE3 |

GEnx-1B64/P2 |

Trent 1000-D2 |

GEnx-1B70/P1 |

|

GEnx-1B76A/P2 |

|

Trent 1000-C |

GEnx-1B67 |

Trent 1000-D3 |

GEnx-1B70/P2 |

|

|

|

Trent 1000-C2 |

GEnx-1B67/P1 |

Trent 1000-J2 |

GEnx-1B70/75/P2 |

||

|

Trent 1000-CE3 |

GEnx-1B67/P2 |

Trent 1000-J3 |

GEnx-1B74/75/P1 |

||

|

Trent 1000-D |

GEnx-1B70 |

Trent 1000-K2 |

GEnx-1B74/75/P2 |

||

|

Trent 1000-D2 |

GEnx-1B70/P1 |

Trent 1000-K3 |

GEnx-1B76A/P2 |

||

|

Trent 1000-D3 |

GEnx-1B70/P2 |

|

|

||

|

Trent 1000-E |

GEnx-1B70C/P1 |

||||

|

Trent 1000-G |

GEnx-1B70C/P2 |

||||

|

Trent 1000-G2 |

GEnx-1B70/75/P1 |

||||

|

Trent 1000-G3 |

GEnx-1B70/75/P2 |

||||

|

Trent 1000-H |

|

||||

|

Trent 1000-H2 |

|||||

|

Trent 1000-H3 |

|||||

|

Trent 1000-L2 |

|||||

Rolls-Royce Trent 1000 Engines

As noted above, the first flights of each 787 variant were powered by a variant Rolls-Royce’s Trent 1000 engine series, engines described by the manufacturer as “draw[ing] on [the company’s] technology and experience” with the four prior generations of the Trent engine. Further promoted by Rolls-Royce as being “optimized specifically to power the 787” and allowing it to be “20% more efficient than the Boeing 767 it replaces,” the Trent 1000 also has, at 10:1, the “highest bypass ratio of any Trent engine.” Indeed, Rolls-Royce states that the higher bypass ratio enables the Trent 1000 to be the “quietest engine on the 787 today.” In terms of thrust generated, more than “85% of the engine’s thrust is generated by the 2.8-m [approximately 9.2-ft.] diameter fan.” The company also claims that the three-shaft architecture of the Trent 1000 is better able to “support ‘all electric’ aircraft [like the 787] with a blessless engine system.”

Since it entered service with ANA in 2011, the Trent 1000 series has undergone several improvements, with those changes designated by Rolls-Royce as the Package B and C configurations, as well as the Trent 1000 TEN. The changes made as a part of the Package B improvements primarily involved fuel consumption, while Package C improved specific fuel consumption (SFC) and provided the increased thrust necessary for the engine to power the 787-9. According to Rolls-Royce, the Trent 1000 TEN (Thrust, Efficiency and New Technology) is “not an improvement package;” rather, “it is a step-change in design and performance” that incorporates “design architectures” from the Trent XWB engine that powers Airbus’ A350. To that end, the Trent 1000 TEN “employs a scaled version of the IP [intermediate-pressure] and HP [high-pressure] compressors from the Trent XWB-84,” with other technological improvements coming from the company’s Advance3 demonstrator. The high-pressure turbine (HPT) “architecture is shared with the Trent XWB-97” and promoted as enabling “better component life results for the Trent 1000 in service.” In comparison to the Package C production standard engine, the Trent 1000 TEN is designed to improve fuel burn by 2%.

Following its test program, Rolls-Royce announced on Aug. 19, 2017, that it had received EASA certification for the Trent 1000 TEN, with the engine subsequently entering service in November 2017. Air New Zealand, Norwegian and Singaporean low-cost carrier Scoot were among the first airlines to operate Trent 1000 TEN-equipped airframes. Also in 2017, Rolls-Royce transitioned Trent 1000 production from the Package C configuration to the TEN. According to the 787’s type certificate data sheet (TCDS), the takeoff static-thrust limit—based on a standard day and sea-level altitude—varies between 59,631 lb. for the Trent 1000-E that powers the -8, and 78,129 lb. for the Trent 1000-J2, J3, K2 and K3 on the -9, and J3 and K3 on the -10.

General Electric GEnx

The other engine option for the 787, GE’s GEnx-1B, is promoted as offering a number of benefits, including SFC that is a 15% improvement in comparison to “the engine it replaces”—the company’s CF6—while also being able to “stay on-wing 20% longer” and “using 30% fewer parts.” As is the case for the Trent 1000 series, the GEnx-1B also incorporates improved technologies and materials, with the goal of improving performance and efficiency, while reducing the engine’s fuel consumption and weight. The technologies incorporated into the engine include a twin-annular pre-swirl (TAPS) combustor—which is touted as reducing nitrogen oxide (NOX) emissions—while the front fan case and fan blades are both made from carbon-fiber composites, with the use of composites in those two components noted as being a first for a commercial jet. GE Aviation further describes the carbon-fiber fan blades, which are reduced in number from 22 to 18, as incorporating an updated design that improves efficiency, while the composite fan case allows for the weight to be further reduced. The efficiency and weight improvements of the GEnx are further enhanced by the engine’s low-pressure turbine (LPT), which is promoted as “incorporat[ing] next-generation 3D aerodynamics.” Additionally, in the LPT’s sixth and seventh stages, titanium aluminide blades are utilized, the use of which results in a weight reduction of 400 lb., as well as an increase in fuel efficiency. Based on the same criteria noted above for the Trent 1000, the GEnx-1B engines certified for 787 vary in takeoff static thrust from 67,000 lb.—for the 787-8’s GEnx-1B64, -1B64/P1 and -1B64/P2—and 78,500 lb., with the latter limitation being applicable to the GEnx-1B76A/P2 that powers both the -9 and -10, as well as the -1B76/P2 that is only certified for the -10.

System Design

Beyond the engine advancements noted above, the 787 also relies less on the bleed air from the engines—with the design described by Boeing as being “more electric” and not featuring a traditional pneumatic system—an arrangement known as being “bleedless.” Using a “no-bleed architecture, the engines provide the majority of airplane systems power needs in electrical form via shaft-driven generators.” In comparison to systems “that were powered by bleed air or hydraulics” on the 777, systems including airframe ice protection, cabin air conditioning, engine start, horizontal stabilizer trim, pressurization, wheel brakes and wing anti-ice are electrically powered on the 787. For starting 787’s engines, traditional pneumatic starters have been “replaced with a pair of gearbox-mounted main-engine starters/generators.” The benefits of the no-bleed electrical systems include improved efficiency—“the 787 systems architecture accounts for predicted fuel savings of about 3%”—and reliability, as well as lowered maintenance costs and weight. Boeing says the use of electrical power in lieu of engine-generated pneumatic power is “more efficient” and will result in the extraction of “as much as 35% less power from the engines.” On the 787 series, non-electric systems include nacelle inlet anti-ice protection, a system which “occasionally” uses engine bleed air.

Composite Use

As for the 787’s increased use of composites, Boeing notes that the airframe “is 50% composite by weight,” with composites representing “a majority of the primary structure” including the fuselage and wing. The use of composites in the type’s wing is noted as allowing it to have a higher aspect ratio of 10:1 that gives it “better lift-to-drag performance,” with the lift-to-drag ratio being “5% better” that on the 777. Similar to the use of carbon-fiber composites in the GEnx engines, the benefits of using composites on the 787 airframe include efficiency gains and fuel-burn reduction due to the composite material’s lighter weight. Further benefits are found when it comes to maintaining the airplane, with Boeing pointing out the fact that composite materials “do not fatigue or corrode,” resulting in less scheduled maintenance. The overall costs of operating the 787 are also promoted as being reduced, with operating and maintenance costs reduced by 15% and 30%, respectively.

Distinctions Between 787 Variants

Although the -8 is the smallest 787-series airframe in terms of passenger capacity, from a performance perspective its published range makes it the middle-of-the-range option of the series. Described as having the capability to “grow routes first opened with the 787-8,” the larger -9 represents a 20-ft. stretch in comparison the first 787 variant, with that stretch enabling it to carry 48 more passengers in a typical two-class configuration. The increased space afforded by the -10’s 18-ft. stretch—in comparison to the -9—allows for passenger capacity in a two-class configuration to be increased by another 40 seats to 336.

Program Issues

While the 787 has been a commercial success for Boeing, the program has encountered multiple issues since it first entered service, including several related to the Trent 1000 engine. Prior to the discovery of those engine issues, however, the program encountered battery problems that resulted in the type being grounded for over three months in 2011. Following a Jan. 7, 2011, fire at Boston’s Logan International Airport that involved the auxiliary power unit (APU) battery of a JAL 787, as well as an issue with the main battery on an ANA domestic flight six days later that necessitated a diversion, the fleet—which at the time stood at 50 airplanes—was grounded. However, rather than redesigning the 787’s electrical architecture, Boeing redesigned the airplane’s two 32-volt lithium-ion batteries, as well as the enclosures they are contained in. The updates “include a 1/8-in.-thick stainless steel battery enclosure,” battery charger, vent-line assembly, wire bundles and associated hardware, with the enclosure itself “designed to meet a 300C [572F] event without thermal risk to the aircraft.” In the aftermath of the grounding, 787 deliveries resumed on May 14, 2011, with the delivery of ANA’s 18th -8, while revenue operations for the type resumed with an Ethiopian Airlines flight on April 27.

Issues with the 787’s Trent 1000 engines include those which are associated with the Package B and C upgrades, as well as others that have been discovered on the newer Trent 1000 TEN design. Durability issues related to those upgrade packages have been found in the intermediate and high-pressure turbine (IPT/HPT) blades, as well as in the intermediate-pressure compressor (IPC). The durability issues related to the IPT blade involve chemical corrosion—sulphidation—that Rolls-Royce noted is “caused by pollutants in the air” and was addressed by the company “introduc[ing] a new blade design featuring an improved protective coating.” The durability issue affecting the HPT blades, which resulted in the deterioration of the blades “earlier than expected,” also necessitated a new blade design, which was “made available in October 2018.” The problems related to the IPC involved the fact that, “under certain conditions the blades could vibrate, which caused a few of them to crack.” The Trent 1000’s IPC issues affected both Package B and C engines, with Rolls-Royce announcing in January 2019 that they have received approval for a redesigned IPC blade for Package C engines. Additionally, while no problems have been found on the IPC blades of the more recently certified Trent 1000 TEN variants, the IPC blades of those Trent 1000s would also be replaced “as a precautionary step.”

Although no problems have been found with the Trent 1000 TEN’s IPC blades, deterioration issues were found on the TEN’s HPT blades in the spring of 2019, resulting in launch customer Singapore Airlines deciding to ground two of the 787-10’s for inspections. Following the discovery of the Trent 1000 TEN’s HPT issues, Rolls-Royce “agreed to a new inspection regime for this engine design,” while also “developing and testing an enhanced version of the blade” that was anticipated to be “retrofitted into the fleet in early 2020.” The company announced in November 2019, following the completion of “a detailed technical evaluation” of the redesigned HPT blade that revealed that it would not “deliver a sufficient level of enhanced durability…that an improved blade is unlikely to ready before the first half of 2021.” As a result of these concerns, “dozens” of 787s remained grounded in early 2019, with the number of grounded airframes “believed to have peaked at about 50.” Beyond grounding a significant number of airframes, the Trent 1000 problems have also resulted in a reduction in extended operations (ETOPS) limitations, causing additional service disruptions for 787 operators.

Beyond the 787’s engine-related issues, Boeing has also had to pause deliveries of the type several times, including a four-month suspension—from January to May 2013—as a result of the previously discussed lithium-ion battery issues. Problems related to production quality have also been an issue since 2019—“how parts or major subassemblies fit together”—with an additional pauses in deliveries occurring from October 2020 to March 2021, and again from June 2021 to August 2022. Those latter halts in production—which have cost the company “around $5.5 billion” in losses—were “mostly concerned with surface quality defects, shims, gaps and out-of-tolerance components.” The second production pause was brought to an end on March 27, 2021, with the delivery of a 787-9 to United, Serial No. 66144 and registered as N29985.

That resumption of 787 deliveries in 2021 was rather brief, as Boeing once again suspended deliveries in June 2021. While the issues identified do not represent “a safety-of-flight risk” to in-service airframes, “every aircraft built has required at least some rework to bring it up to Boeing’s production standard.” On July 29, 2022, the airframe manufacturer was granted “FAA approval on its plan to inspect undelivered 787s and correct production-quality issues to prepare them for delivery,” a step that allowed deliveries to resume in August 2022. Following the receipt of that approval, the first 787 delivery—a 787-8, Serial No. 66000 and registered as N880BJ—was made to American Airlines on August 10, 2022. At the time that Boeing received FAA approval to fix the issues that resulted in deliveries being suspended, the company had over 100 undelivered 787s.

Environmental Performance

In addition to its performance capabilities, Boeing also promotes the 787 series as having a reduced environmental impact with regard to both emissions and noise. To that end, the 787 series is touted by Boeing as having a noise footprint that is “60% smaller than the airplane that it replaces.” The company also notes that “sounds of 85 dB [decibels] or higher never leave airport boundaries,” while a UK Civil Aviation Authority (CAA) report that stated that “[t]he 787 is on average up to 7 dB quieter on departure than the 767, and 8 dB quieter than A330 aircraft.” Additionally, the same CAA report notes that the 787 is “up to 3 dB quieter on arrival than the aircraft types it is intended to replace.” The emissions reductions of the 787 are enabled, in part, by the improvement in fuel economy, improvements that differ based on the variant. Boeing promotes the smaller -8 and -9 variants as reducing fuel burn and emissions by 20%, with the -8’s reductions in those areas being compared to “the airplanes it replaces.” Conversely, the -9’s reductions in emissions and fuel use are noted as being in comparison to “similarly sized airplanes.” For the -10 variant, the emissions and fuel burn are noted as being improved by 25% when compared to the airframes that the variant is designed to replace, while also being promoted as a 10% improvement in comparison to “the best on offer by the competition.”

Program Status/Operators

Unlike other Boeing commercial airplanes, production of the 787 is split between manufacturing facilities in Everett, Washington, and North Charleston, South Carolina. Specifically, Boeing’s facilities at Paine Field produce the -8 and -9, while the larger -10 is exclusively produced at the company’s facilities in South Carolina. The company’s North Charleston production line was announced on Oct. 28, 2009, with the facility completed in June 2011 and the first South Carolina-produced airframe rolled out on April 27, 2012. The first delivery of a 787 produced in North Charleston, a -8 to Air India, was announced by the company on Oct. 5, 2012. Although Boeing has maintained production lines for the airframe in both Washington and South Carolina since the latter facility opened, the company announced on Oct. 1, 2020, that it would “consolidate” all 787 production in North Charleston beginning in “mid-2021.”

The 787-8’s flight-test program involved the largest number of flight-test airframes, with a total of six—designated ZA001-ZA006—used to perform the testing required for certification. Of those six flight-test airframes, four were equipped with Trent 1000 engines (ZA001-ZA004) and two (ZA005 and ZA006) were powered by GEnx-1B engines. The second -8 test airframe, which was designated ZA002 and registered as N787EX, made its first flight on Dec. 22, 2009, while the fourth 787 built—ZA004, registered as N7874—became the third of the type to fly when it made its first flight on Feb. 24, 2010. Several years later, in 2014, ZA004 was used as part of Boeing’s ecoDemonstrator program that evaluates “new technologies [that are] aimed at improving aviation’s environmental performance.” The fourth 787 to fly, designated ZA003 and registered as N787BX, made its first flight on March 14, 2010; while ZA005—registered as N787FT—the first GEnx-1B-powered 787, made its first flight on June 16, 2010. According to Boeing’s press release announcing the first flight of ZA005, the airframe was to “be used to test the [GE] engine package and demonstrate that the changes made with the new engine do not change the airplane’s handling characteristics.” The final flight-test airframe—ZA006, registered as N787ZA— made its first flight from Paine Field on Oct. 4, 2010, and represented the second GEnx-1B-powered test airframe. In comparison to the number of airframes used in the -8’s flight-test program, the -9 required five airframes to perform its 1,500-hr. flight-test program: three designated flight-test airframes and two production airframes. Those latter airframes—the fourth and sixth -9s produced—were eventually delivered to ANA and Air New Zealand, respectively. In addition to the flight-test airframe that performed the -9’s first flight—ZB001—the second and third test airframes were designated ZB002 and ZB021, with ZB002 being Trent 1000-powered and registered as N789FT. The 787-10’s flight-test program involved three airframes, the Trent 1000-powered ZC001 and ZC002, as well as the GEnx-1B-powered ZC036, the latter two of which were registered as N565ZC and N548ZC, respectively.

References

- AWIN Article Archives

- Airbus, Boeing, GE Aviation and Rolls-Royce Commercial Materials

- FAA TCDS (787, Trent 1000)

- EASA TCDS (A330)

admin

admin