Airbus A380

Airbus A380 user+1@localho… Thu, 11/11/2021 - 21:17 The A380 is a four-engine, widebody airliner produced by European manufacturer Airbus. Referred to as the A3XX prior to its launch on Dec. 19, 2000, the airframe was originally promoted as...

The A380 is a four-engine, widebody airliner produced by European manufacturer Airbus. Referred to as the A3XX prior to its launch on Dec. 19, 2000, the airframe was originally promoted as being offered “in five passenger versions, with capacities ranging from 481 to 656 seats,” as well as in a freighter configuration capable of carrying “a 150-[metric ton] payload.” At the time of its launch, it was anticipated that the A380 would make its first flight in 2004 and enter into service in 2006. Fifty commitments from six airlines—including Air France, Emirates, Qantas, Singapore Airlines and Virgin Atlantic—were received by the time the program was launched.

Despite the originally announced entry-into-service date, a number of issues pushed the first flight back into 2005, and entry into service to late 2007. On Jan. 18, 2005, the first A380—MSN001, registered as F-WWOW and powered by Rolls-Royce Trent 900 engines—was unveiled at Airbus’ production facilities at Toulouse-Blagnac Airport in France, some three months in advance of the first flight. When it flew for the first time on April 27, 2005, it was not only the first flight of the airframe, but also signified the A380 becoming the world’s largest passenger-transport airplane. Two engine options are certified for the A380—Engine Alliance’s GP7200 series and Rolls-Royce’s Trent 900 series—with the latter series powering the first two variants that were certified in 2006. The first flight of a GP7200-powered A380—MSN009, then-registered as F-WWEA— took place on Aug. 25, 2006, a little over a year after the first flight of a Rolls-Royce powered airframe, with the certification of the Engine Alliance-powered variant similarly one year behind. The airframe itself progressed from its first flight to certification in under 20 months, with the first A380—powered by Rolls-Royce engines—being handed over to Singapore Airlines on Oct. 15, 2007, at Airbus’ facilities in Toulouse. Ten days later, that airframe—MSN003 and registered as 9V-SKA—performed the A380’s first commercial flight between Singapore and Sydney. On July 28, 2008, at Airbus’ delivery center in Hamburg, the first GP7200-poweed A380 was delivered to Dubai-based Emirates, which placed the airframe into service between Dubai and New York’s JFK International Airport on Aug. 1, 2008. According to the A380’s European Union Aviation Safety Agency (EASA) type certificate data sheet (TCDS), the A380’s type certificate is held by Airbus S.A.S. of Blagnac, France.

|

A380 Variant |

EASA Certification Date |

|

A380-841/-842 |

Dec. 12, 2006 |

|

A380-861 |

Dec. 14, 2007 |

Cabin

According to the airframe’s EASA TCDS, the A380 is certified for a maximum passenger capacity of 868, with the breakdown between the upper and lower deck noted below. Despite having that maximum certified passenger capacity, Airbus promotes the cabin as being “designed for the modern standard of comfort,” while also stating that the typical seating range in a four-class configuration is 400-550 and the standard seating capacity is 555. Airbus’ airport planning document for the A380 notes that the standard seating is divided between 356 seats on the main deck (22 first-class seats and 334 tourist-class seats) and 199 on the upper deck (96 business-class seats and 103 tourist-class seats), for a total of 22 first-class seats, 96 business-class seats and 437 tourist-class seats. The pressurized fuselage volume is 74,161 ft.3, while the combined passenger-compartment volume of the upper and lower decks is 46,086 ft.3

According to Airbus, the combination of the main deck’s height and width provides for “15% more personal space for passenger [item] storage, increased head room and even wider stairs.” In a four-class layout, the A380’s cabin is described as able to “accommodate the growing demand for a premium economy section,” while also providing room for a business-class cabin that features “full-flat beds.” The standard width of seats in the airframe’s economy-class cabin is 18 in., while the cabin’s volume “allows carriers to further distinguish their first-class cabin with a truly distinct luxury product” that can include “private suites” and a “bar and social area.” Beyond the space available in the cabin and the outfitting options available to operators, passenger comfort is also enhanced by the fact that the “cabin air is recycled every two minutes to keep the atmosphere fresh,” with the airframe including “six high-level air outlets, as opposed to the industry standard of two.”

Avionics

For the flight crews that operate the A380, the airframe shares “a large degree of commonality in systems, flight deck [and] procedures with the fly-by-wire A320, A330/A340 and A350 families.” One of the benefits of that commonality is that “pilots do not need extensive amounts of training to transfer from one aircraft type to another,” with the additional training that is required varying between five and 15 days, depending on the airplane that a pilot formerly flew. Beyond the reduced transition time between types—and the corresponding reduced training costs—another benefit of Airbus’ cross-crew qualification and mixed-fleet flying capability is that it increases flight crew productivity.

One example of the ergonomic familiarity that pilots flying other Airbus types experience in this larger airplane is that the “sidestick control is the same distance from the throttle as” is found in other Airbus airplanes. The technology included on the A380’s flight deck is promoted as “incorporat[ing] modern advances in technology for displays, flight management systems and navigation.” Those advances are integrated into the “eight identical large interactive displays” that “provide a much wider panoramic view with clearer presentations, augmented by a head-up display that increases pilot situational awareness, particularly during the approach and landing phases” of flight. Those displays are liquid crystal displays (LCD) that measure 7.25 X 9.25 in., with the eight displays being comprised of dual primary flight displays, multifunction displays and navigation displays, as well as single engine parameter and systems displays. Additionally, cursor control for the for the displays is “provided though a trackball.”

Mission and Performance

Given its size, range and four-engine configuration, the A380 is utilized on long-range and ultra-long-range trunk routes that can support the type’s capacity. Described as being able to “boost network connections,” optimize hubs and enable airlines to “capture more traffic,” the markets that the A380 “was designed to serve [are] hub-to-hub connections on the highest-yield routes between rapidly expanding megacities.” The fact that the A380 offers “60% more capacity per slot” allows operators to replace “multiple flights of smaller aircraft with one optimized service.” In addition to better utilizing slots at operationally limited airports, the use of an A380 on what Airbus describes as the “strongest flight of the day” is promoted as allowing operators to “draw more traffic and capture higher yields.” Overall, the capabilities of the A380 and the fact that it has “a 15% lower cost per seat than its rival large airliner,” is promoted as allowing airlines to “reshape their networks, optimize slot value at congested airports and maximize revenue across entire networks.”

|

Competitive Comparison: Airbus A380 and Boeing 747-8 |

||

|

|

A380-841/-842/-861 |

747-8 |

|

Maximum Passenger Capacity |

868 |

605 |

|

Maximum Range (nm) |

8,000 |

7,730 |

|

Engines (4x) |

Rolls-Royce Trent 900/ Engine Alliance GP7200 |

General Electric (GE) GEnx-2B |

|

Maximum Takeoff Weight (MTOW)(lb.) |

1,267,658 |

987,000 |

|

Wingspan |

261 ft. 8 in. |

224 ft. 5 in. |

|

Length |

238 ft. 7 in. |

250 ft. 2 in. |

|

Height |

79 ft. 1 in. |

63 ft. 6 in. |

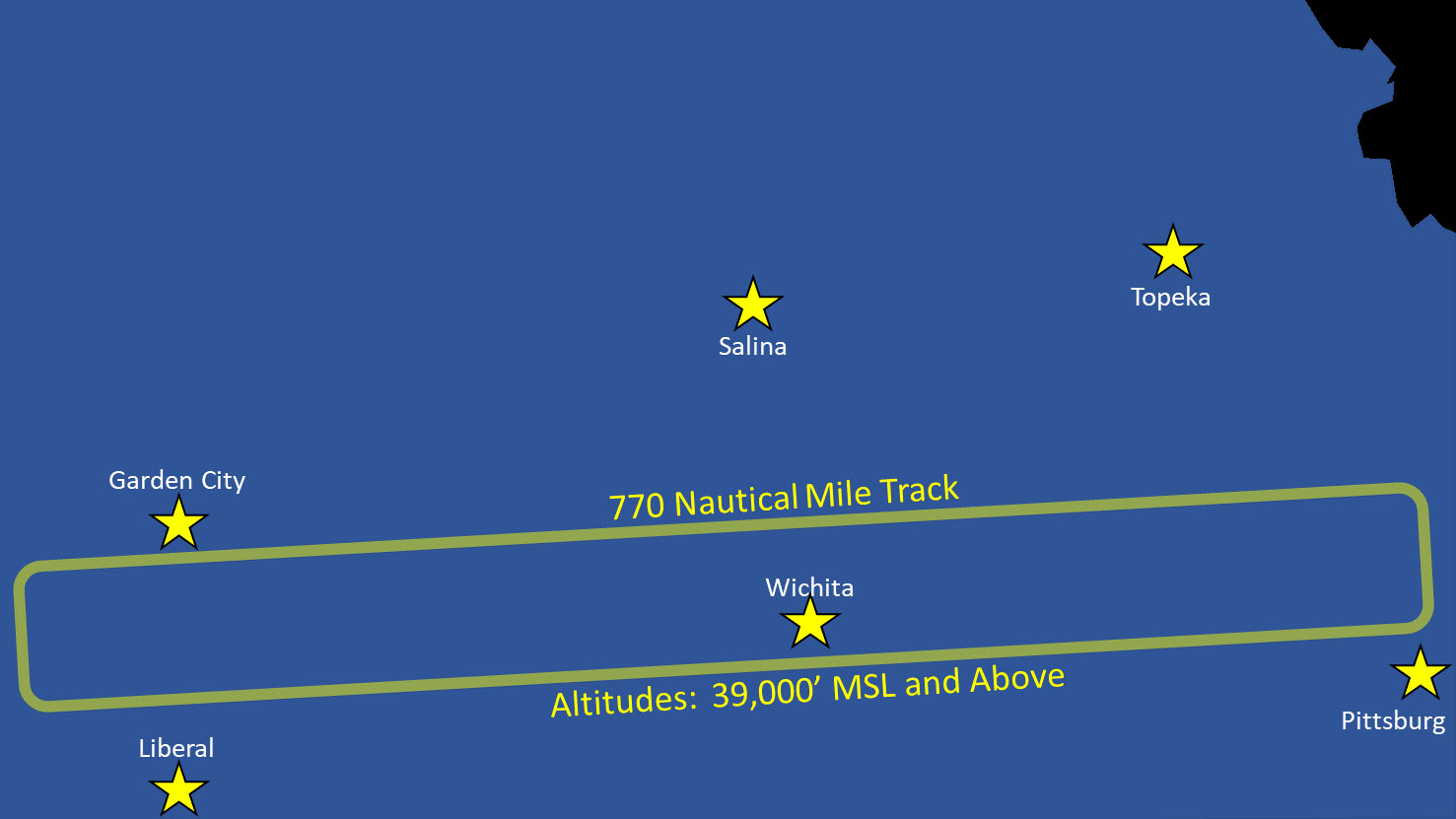

In addition to its 8,000-nm range, the A380 has a number of other performance limitations, including a maximum operating speed (MMO) of 0.89 Mach and a maximum operating altitude of 43,000 ft. Although Airbus does not publish takeoff and landing performance data for the airframe, they do note that the A380 features runway-management technology that is marketed as “Brake to Vacate.” That technology is promoted as “allowing flight crews to more effectively manage approach and landing by pre-selecting the optimum runway exit,” a feature that “can reduce runway occupancy time by up to 30%.”

Variants

|

A380 Specifications |

|||||||

|

|

A380-841 |

A380-842 |

A380-861 |

||||

|

Maximum Certified Passenger Capacity |

868 (Upper Deck: 330/Main Deck: 538) |

||||||

|

Maximum Range (nm) |

8,000 |

||||||

|

Engines (4x) |

Rolls-Royce RB211 Trent |

Engine Alliance GP7270 |

|||||

|

970-84 |

970B-84 |

972-84 |

972B-84 |

972E-84 |

|||

|

Takeoff Static Thrust (lbf.) (Sea Level) |

75,152 |

78,304 |

76,752 |

80,213 |

76,752 |

74,735 |

|

|

Maximum Takeoff Weight (MTOW)(lb.) |

1,267,658 |

||||||

|

Maximum Landing Weight (lb.) |

870,826 |

||||||

|

Wingspan |

261 ft. 8 in. |

||||||

|

Length |

238 ft. 7 in. |

||||||

|

Height |

79 ft. 1 in. |

||||||

Engine Alliance GP7200

Engine Alliance, a joint venture between General Electric (GE) and Pratt & Whitney that was created for the purpose of manufacturing an engine for the A380, produces the GP7200 engine series for the airframe. Marketed as being “the quietest, most reliable, [and] most fuel-efficient engine for the A380,” the GP7200 series includes technology from the GE90 and PW4000 series of engines. The fuel savings of the GP7200 series—which, in addition to the GP7270, includes the GP7272 and GP7277—are quantified by Engine Alliance as being “up to $500,000” annually for every equipped airplane, with emissions reduced to below the Committee on Aviation Environmental Protection’s CAEP/8 requirements. Specifically, Engine Alliance promotes GP7200-equipped A380s as “saving the environment 1,900 metric tons of CO2[carbon dioxide] every year.” In addition to that reduction in CO2 emissions, the noise produced by the engines is also reduced, with the level—17.6 dB below the Stage 4 noise requirements—marketed as providing “a whisper quiet flying experience.”

According to the type certificate that is held by East Hartford, Connecticut-based Engine Alliance, the GP7270 is an “axial-flow, dual-spool, turbofan engine” that incorporates a single annual combustor and a fan that has a single stage. Other GP7270 components include low- and high-pressure compressors that have five and nine stages, respectively, while the low-pressure turbine has six stages and the high-pressure turbine has two.

Rolls-Royce Trent 900

Roll-Royce’s A380 engine option, the Trent 900, is the “fourth member of the Trent family,” with technologies that are “proven to reduce noise and weight, while increasing efficiency.” One of the reasons that the Trent 900 reduces noise is because the engine’s 24 fan blades are of “a new swept design that reduces the effect of shock waves as the tip of the fan rotates supersonically.” Rolls-Royce also promotes the fuel-burn improvements that have been made since the engine series entered service, improvements that it quantifies as being “up to 1.6%.” Further upgrades to the Trent 900 were introduced in 2014—an upgrade that used the Trent 900EP2 commercial designation—with an additional upgrade entering service in December 2016. That second upgrade, marketed as the Trent 900 EP3 and representing “the standard production model of the engine,” incorporates a number “of improvements, including optimized blade-tip clearances and blade leading-edge aerodynamics, improved turbine case cooling, improved sealing for the low-pressure and intermediate-pressure turbines, an optimized intermediate-pressure (IP) compressor, an improved engine sector stator and improvements to the air-flow system.” Much as Engine Alliance does with the GP7200 series, Rolls-Royce promotes its A380 engine offering as providing “the lowest lifetime fuel-burn on” the airframe. Furthermore, if a Trent 900-equipped airframe needs an engine replaced at an airport where a replacement is not available, Rolls-Royce notes that it is “the only A380 engine that can be loaded into a 747 freighter without disassembly.”

According to the EASA TCDS for the Trent 900 series, the engine is a “three-shaft, high-bypass-ratio, axial-flow turbofan” engine that, much like the GP7270, has a single annular combustor. The low-, intermediate- and high-pressure compressors—which have one, eight and six stages, respectively—are “driven by separate turbines through coaxial shafts.” The low-pressure fan diameter is 9.68 ft. (2.95 m), with the amount of noise lowered and the efficiency increased because of the fan’s “swept fan blade” and outlet guide vanes (OGV). In comparison to the compressor portions of the engine, the low-pressure turbine has five stages, while the intermediate- and high-pressure turbines each have single stage. From the aft portion of the engine, the intermediate- and low-pressure “assemblies” rotate in a different direction (counterclockwise) than high-pressure “assembly,” the latter of which rotates in a clockwise direction.

A380 Characteristics and Limitations

The primary distinction between the three certified variants of the A380 involves whether they are equipped with Rolls-Royce or Engine Alliance engines. Despite the fact that the Engine Alliance GP7270 has a lower takeoff static thrust rating at sea level—an amount of thrust that can be maintained for up to 5 min.—all three variants share the same 1,267,658-lb. (575-metric ton) MTOW and 870,826-lb. (395-metric ton) landing weight. The A380’s ability to operate long-range and ultra-long-range routes is enabled, in part, by its 85,707-gal. (572,035-lb.) usable fuel capacity.

In comparison to the volume of the passenger-seating areas, the useable volumes of the three cargo compartments—forward, aft and bulk—are 3,157 ft.3, 2,525 ft.3 and 505 ft.3, respectively, with the volumes of the forward and aft compartments “based on LD3” containers. The A380 is able to carry 38 such containers in the underfloor space, while 13 pallets can be accommodated in the same space. According to the FAA TCDS for the type, the maximum load for the forward cargo compartment is 63,000 lb., 44,775 lb. for the aft cargo compartment and 5,540 lb. for the rear (bulk) cargo compartment.

From a design perspective, the A380-800’s wing is “much larger than necessary for the baseline -800” because it was it was designed to accommodate the stretched -900 variant of the airframe. The result of that wing design was that the -800 is “heavier and significantly less efficient than would have been possible with a smaller wing optimized for its fuselage size.” At the time of the first A380 delivery, 25% of the airframe was considered to be composite by weight, with the composite portions of the airframe including “doors and tail surfaces,” sections of the fuselage and the wing and wing box. Specific to the wings, “carbon fiber-, glass fiber- and quartz fiber-reinforced plastics were used,” while the A380 represented the “first commercial airliner” to have a wingbox made from carbon-fiber reinforced plastic (CFRP).

Potential Upgrades

During the time it was in production, a number of possible upgrades were discussed for the A380, upgrades that would have resulted in changes to the cabin configuration, engines and wings. In June 2017, Airbus unveiled the results of a study “for an enhanced A380,” which was called the A380plus. The improvements that would have been part of that upgrade program involved changes to the airframe’s wings and cabin, as well as the intervals at which the maintenance is required to be performed. Changes to the A380’s wings included the addition of “new winglets [that] measure approximately [15.4 ft.] in height,” which are “designed to improve aerodynamics and reduce drag.” The result of the A380plus’ aerodynamic improvements, “in particular, new large winglets and other wing refinements,” would have “allow[ed] for up to 4% fuel-burn savings.”

Cabin changes—including “redesigned stairs, a combined crew-rest compartment, sidewall stowage removal [and] a new nine-abreast seating configuration in premium economy and 11-abreast in economy”—could have allowed for as many as “80 additional seats.” The inclusion of all “cabin enablers” would have increased the average capacity of the airplane, in a four-class configuration, from 497 to 575, an increase that would have allowed operators to “generate significantly more revenue.” In order to carry those additional passengers to the airframe’s 8,200-nm maximum range at the time, an MTOW increase of more than 6,600 lb.—to 1,274,272 lb. (578 metric tons)—would have been required. In lieu of accommodating additional passengers, the 578-metric ton MTOW would also enable the A380plus to fly 300 nm further than that maximum range. Supplementing the changes to the airframe itself, maintenance intervals would have also been increased, including “a reduced six-year check downtime and system improvements,” changes promoted as “reduc[ing] maintenance costs and increase[ing] aircraft availability.” The overall impact of the A380plus upgrade would have reduced costs, on a per-seat basis and compared to the current A380, by 13%.

A380 Freighter

Beyond the passenger variants of the A380, Airbus also previously planned to develop a freighter version of the airframe. In the early stages of the program, the freighter variant had as many as 27 orders, including 10-airframe orders from both FedEx Express and UPS. The former operator’s January 2001 order represented the launch order for the A380 freighter, with deliveries originally scheduled to begin in 2008. According to Airbus’ press release announcing the order, Memphis-based FedEx was scheduled to receive three airframes in 2008, 2009, and 2010, with the company’s final A380 freighter scheduled for delivery in 2011. However, FedEx cancelled its commitment in November 2006 because of program delays, with UPS taking the same action the following year due to a lack of confidence in Airbus’ ability to meet a revised delivery date for the first airframe. When the order was first announced in January 2005, it was noted that Atlanta-based UPS was scheduled to receive its first A380 in 2009. After UPS’ March 2007 decision to cancel its order for A380 freighters—which were to be powered by Engine Alliance’s GP7272 engines—Airbus decided to freeze the development of the variant indefinitely. In addition to the direct implications that decision had on the freighter variant, that indefinite delay also impacted the derivative A380-900 passenger variant, which would have used the freighter variant as its “baseline.” With reference to the planned specifications of the A380 freighter, Airbus noted in 2005 that it was to be able to “carry a freight load of 330,000 lb. on three decks, with a cargo volume capacity of 40,000 ft.3, a distance of 5,600 nm.”

Environmental Performance

Another A380 selling point that was promoted by Airbus is its environmental friendliness, with the airframe described as being “the quietest widebody jetliner flying today.” Specific to the noise created by the four Engine Alliance and Rolls-Royce engines, they “generate 50% less noise energy on departure than its nearest competitor, as well as 3-4 times less when landing.” In addition to being able to “meet the increasingly important environmental standards for air transportation today and in the future,” the passenger capacity of the A380 allows it to “alleviate traffic congestion at busy airports by transporting more passengers at the lowest costs.” As is noted above, the airplane also allows operators to maximize the utilization of takeoff and landing slots at operationally restricted airports such as London Heathrow, with the “ever-increasing number of passengers” able to be carried “without proportionally increasing the number of flights.”

Program Status/Operators

A380 airframes were assembled alongside all other Airbus widebody airframes—as well as the A320—at the company’s facilities in Toulouse. The airplanes were then flown to Hamburg Finkenwerder Airport, where they were painted and the fitting out of the interior took place. The A380’s flight-test program, which began with the first flight in April 2005, was conducted using five airframes—four powered by Rolls-Royce engines and one equipped with Engine Alliance engines—that performed 2,600 hr. of flight testing by the time the first variants were certified in late 2006. Following the April 2005 first flight of the type, the second A380 (MSN004, registered as F-WWDD) took place on Oct. 18, 2005, with the third Rolls-Royce-powered A380 (MSN002, registered as F-WXXL) flying just a few weeks later on Nov. 3, 2005. MSN002 was the first A380 to be equipped with a “consumer-ready interior,” while the fourth and final flight-test airframe to have Rolls-Royce engines (MSN007, registered as F-WWSD when used as a flight-test airplane) first flew on Feb. 19, 2006. Furthermore, when the first A380 was delivered to Singapore Airlines in October 2007, the flight-test fleet had logged over 4,000 flight-test hours. One benefit of the delays noted below is that they allowed Airbus to increase the number of flight-test hours, allowing the company to put “the A380 through the wringer, logging a large number of flight hours, gaining valuable at-airport experience, and running inflight entertainment systems through high-load stresses to ensure that airline customers [did] not have a bad experience.”

While the first variants were certified in late 2006 and the first A380 entered service in late 2007, the program as a whole was delayed by over two years because of “assembly problems” that were encountered by Airbus. The “root cause of the repeated delays” involved “faulty wiring harness designs,” an issue that impacted “the manufacturing and installation of electrical systems and harnesses, which caused ‘bottlenecks’ in the production sequence.” Specific to the wiring harness-related issues, “problems and delays with wiring harnesses caused them to have to be installed after final assembly in a laborious, time-consuming fashion.” Those problems had four points of origination—“design evolutions, flight-test results, ground testing and installation issues”—which, “in each case, forced changes in the design of the wiring harness, which could not be accommodated rapidly enough to install the fixed wiring in time.” With regard to design issues, Airbus’ “digital mock-up did not accurately reflect the aircraft design,” the result of which was that, in some instances, the wiring harnesses “came up short because they had to be rerouted.” Further issues surrounded the decision to use aluminum wiring that is “light weight” instead of copper, a decision that “created difficulties because aluminum has a bigger bending radius.”

Several years after the A380 entered service, it encountered another issue when, on Nov. 4, 2010, a Rolls-Royce-powered Qantas airplane suffered an uncontained engine rotor failure (UERF) 4 min. after departing Singapore for Sydney. As a result of the UERF in one of the RB 211 Trent 972-84 engines, the airframe—MSN014, which was delivered on Sept. 19, 2008, and registered as VH-OQA–sustained “significant structural and systems damage,” requiring an emergency landing back in Singapore. According to the Australian Transportation Safety Board’s (ATSB) final report on the accident, the engine which suffered the failure—the number two engine on that particular A380—was found to have “a number of stub pipes within the high and intermediate-pressure (HP/IP) hub assembly [that] were manufactured with thin wall sections that did not conform to design specifications.” The design flaw in those parts “significantly reduced the life of the oil-feed stub pipe on the number two engine so that a fatigue crack developed, ultimately releasing oil during the flight that resulted in an internal oil fire. The result of that fire was “the separation of the intermediate-pressure turbine disk from the drive shaft.” On the day of the incident, Qantas grounded its entire A380 fleet, which stood at six at the time, including the airframe involved in the accident. The first of Qantas’ undamaged A380s returned to service in late November 2010, while, after more than a year of repairs which cost $143.3 million, the damaged airframe returned to service with the company in April 2012. In addition to the operational disruptions to Qantas, inspections and subsequent maintenance resulted in certain A380s being temporarily removed from service by Lufthansa and Singapore Airlines.

Current and past operators of Engine Alliance-equipped A380s include Emirates—which has the largest fleet of A380s—as well as Etihad Airways, Korean Air and Qatar Airways. While the balance of operators—including All Nippon Airways (ANA), Asiana, British Airways, China Southern Airlines, Lufthansa, Malaysia Airlines, Qantas, Singapore Airlines and Thai Airways International—both current and past, operate airframes that are powered by the Rolls-Royce Trent 900 variants noted above. The first European customer to take delivery of an A380 was Air France, an event that took place on Oct. 30, 2009. Subsequently, Air France placed its first A380 into service between Paris and New York’s JFK airport. A single airline, Emirates, operates both Engine Alliance and Rolls-Royce-powered A380s, with that operator announcing in April 2015 that its 50-airplane order from the 2013 Dubai Air Show would utilize Trent 900 engines. At the time of its announcement, Emirates’ order allowed Rolls-Royce to claim that it had “secured more than 50% market share on the aircraft, in addition to being selected by the majority of A380 customers.” The first Rolls-Royce-powered airframe from that order was delivered to the Dubai-based carrier in December 2016.

Although Airbus announced in January 2008 that four A380s would be produced per month by 2010, that level of production was never achieved. Rather, the number of A380s produced by Airbus began decreasing; first from 2.7 to 2.3 airplanes per month, with a further reduction from 2.3 to 1.7 airframes per month taking effect in November 2016. However, before production could be reduced to the 1.7 airframe-per-month rate, Airbus announced, along with its first-half results for 2016, that A380 production would be reduced even further, to one airframe to per month, starting in 2018. Just one year later, with the July 2017 release of the company’s half-year results, Airbus stated that, starting in 2019, production would be reduced to eight airframes per year, or roughly 0.67 per month. Peak production for the program occurred in 2012 and 2014 when the company delivered 30 A380s. Finally, although it appeared that the airframe would continue to be produced well into the 2020s following Emirates’ February 2018 commitment for a further 36 airframes—20 firm orders and 16 options—a year later Airbus announced that they had reached an agreement with the carrier to convert the bulk of its remaining orders to other widebodies, the result of which would be the cessation of A380 production. That announcement, made on Feb. 14, 2019, stated that, from that point forward, Emirates would only take delivery of a further 14 A380s, for a total fleet of 123 airplanes. While Emirates did place an order for 50 A350-900s, the result of the decrease in A380 orders was that Airbus would shutter production in 2021. The final A380 produced—MSN272 and registered as A6-EVS—made its first flight from Toulouse on March 17, 2021, with delivery of that airframe and MSN271 (registered as A6-EVR) to be completed by the end of 2021.

References

- AWIN Article Archives

- Airbus, Boeing, Engine Alliance and Rolls-Royce Commercial Materials

- FAA TCDS (A380, 747)

- EASA TCDS (A380, Trent 900, GP7200)

admin

admin